Robotics

Advantages of Industrial Robots

Increased efficiency

Industrial robots can complete certain tasks faster and more efficiently than humans as they are designed and built to perform them with higher accuracy. They are used to automate processes which previously might have taken significantly more time and resource to achieve the same results.

Improved quality

Given their higher levels of accuracy, industrial robots can be used to produce higher quality products. This results in the reduction of time required for quality control and ensures that standards of quality are adhered to.

Improved working environment

Some tasks are deemed as too dangerous or laborious and repetitive for humans to carry out and so instead robots can perform these tasks. Working conditions, therefore, can be vastly improved as well as the safety within factories and production plants by introducing industrial robots..jpeg.aspx?lang=en-GB&width=700&height=250)

Increased profitability

The results of introducing industrial robots can only ensure higher profitability levels with lower cost per product.

Longer working hours

On average a 40% increase in the output of a production line occurs when one key person is replaced by a robot who operates the same working hours, simply because of stamina.

Prestige

“Wowing” your clients by operating at the cutting edge of your industry, robots are even fantastic as a marketing tool showing the difference comparing you to your competition.

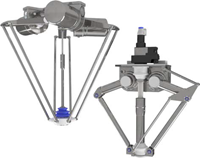

Delta

The main benefit of delta robots is that the heavy motors are fixed on the frame, allowing the moving parts of the robot to be very light. Working at high speeds, delta robots are carefully PLC programmed to work in synchronization with a moving conveyor

The main benefit of delta robots is that the heavy motors are fixed on the frame, allowing the moving parts of the robot to be very light. Working at high speeds, delta robots are carefully PLC programmed to work in synchronization with a moving conveyor

SCARA-Selective Compliance Assembly Robot Arm

SCARA robots are usually used for pick and place, swing and rotate requirements needing high speed and accuracy compared to a 6-Axis robot.

SCARA robots are usually used for pick and place, swing and rotate requirements needing high speed and accuracy compared to a 6-Axis robot.

SCARA robots have similar functions to a human arm with an elbow.

6-Axis robots

Articulated robots, or 6-axis robots, are easier to align to multiple planes, simple to operate and maintain for different applications.

They are able to support larger component movement with increased weight for a wide range of upstream and downstream applications.

Vision

Vision sensors exhibit several characteristics which make them especially effective for factory automation.

Independent Cart Technology

Historically, motion control has incorporated chains, belts, gears and walking-beam mechanics. These mechanical solutions had limited flexibility, wasted energy and led to excessive maintenance costs.

Download the solution PDF here.

MagneMover LITE

Intelligent conveyor system for light payloads (<10kg)

Easy deisgn and setup

Flexible, modular, and scalable

Simple programming and control of thousands of carts

Quickstick

.PNG.aspx?lang=en-GB&width=250&height=150)

Intelligent propulsion and control system

Payloads from tens to thousands of kilograms

Flexible, modular, and scalable

Simple programming and control of thousands of carts

iTRAK

Intelligent Positioning and flexible conveyor system

Deterministic closed loop servo performance

Automatic synchronisation with other motion axes

High dynamic performance and force