Unplanned downtime can be a major cost for manufacturers. Sesseye’s True Cost of Downtime 2022 report estimates that £1.3trn has been lost from uplanned downtime. Major manufacturers experience 20 monthly unplanned downtime incidents per facility and each failure takes longer to recover from.

Unexpected interruptions to the manufacturing process, caused by the sudden breakdown of essential equipment is timely, expensive and inconvenient.

A previous report from Oneserve recorded that 53% of machinery downtime is caused by internal faults.

Equipment failure can be particularly damaging for industries where uninterrupted production is critical. The benefits of monitoring machine health to help predict maintenance requirements include: reduce costs, minimise downtime and improve overall equipment effectiveness (OEE). Staying on top of machinery and equipment health helps to:

Reduce costs

Significantly reduce downtime and maintenance costs and prevent unscheduled shutdowns and equipment failures. Reduce the risk of expensive repairs, out of hours help and loss of production.

Minimise downtime

By detecting issues early, maintenance teams can schedule repairs and replacements during planned downtime, minimising disruption to production.

Improve overall equipment effectiveness

Factory condition monitoring can improve overall equipment effectiveness (OEE) by identifying and eliminating inefficiencies in the production process. It can also enhance product quality and consistency by detecting and addressing deviations from expected performance.

How to stay on top of factory condition monitoring

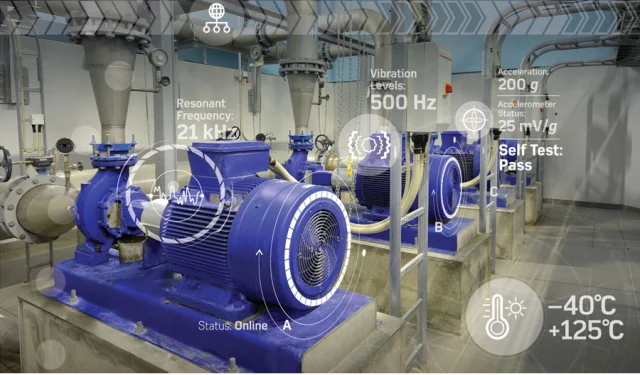

Technology continues to improve, and there are a number of ways to easily stay on top of factory condition monitoring. By analysing real-time data from various sensors and instruments, factory condition monitoring systems can identify trends and anomalies that may indicate impending failures, allowing maintenance teams to intervene before damage occurs.

Contact us to improve your operation

Our experts have the knowledge and experience to evaluate and find the best tools for your specific needs. There’s different factors to consider including the size and complexity of your operation and types of equipment you use but we will find a solution. Complete the form below and we’ll be in touch to help.